Contact Now

Contact Now

Q3110 Drum Type Shot Blasting Machine

I. Application

The high-speed impeller throws the abrasive to the continuous tumbling castings or forgings in barrel, to remove the greensand or scales on the surface. It cleans evenly and its productivity is high, so it is suitable for cleaning the small work pieces whose weight are under 15g in medium or small-scale casting or forging workshops.

As the machine has individual dust-collecting device, the installation spot is not limited by the ventilation pipelines in workshops. The cleaning condition is fine. The machine is equipped with auto-stop device, so it is convenient to operate.

II. Work process

Put the cleaning work piece into the barrel and close the end-cover, and then adjust the cleaning time. First, move the semi-nut needle to the desired position, and then start the machine in turn.

After the barrel rotating, the helical ribs on the protecting board tumble the castings continuously, to make each surface cleaned evenly. Through the hole, the abrasive flows into the middle-wall, then through the screw belt conveying to the box-shaped frame, via elevator carrying to the top of the separator. Screen such big core-sand and burrs, etc, the small sand, dust and abrasive are carried away by the airflow. The integrity shot flows into the blast wheels for continuous usage.

| 1. Diameter of drum: 1000mm |

| 2. Inside length of drum: 800mm |

| 3. Speed of drum: 3rpm/min |

| 4. Max. Effective capacity: 0.1m3 |

| 5. Max. Load (denoting easy-tumbling parts): 300kg |

| 6. Max. Work piece length: 400mm |

| 7. Max. Weight of single work piece 15kg |

| £¨some kind of work piece can be up to 30kg£© |

| 8. Productivity: 600¡«1500kg/h |

| 9.Cleaning time in a cycle(general parts) |

| £¨1£©Iron castings 3¡«10min |

| £¨2£©Steel castings 10¡«20min |

| £¨3£©Forgings 4¡«8min |

| 10¡¢Electric motor |

| £¨1£©Barrel YTL-501 1.1kW£¬48rpm/min |

| £¨2£©Blast wheel J0251-4£¨D2£© 7.5kW£¬1450rpm/min |

| £¨3£©Bag type Dust collector 1.1kW£¬2825rpm/min |

| 11¡¢Elevator |

| £¨1£©Quantity 16 |

| £¨2£©Capacity 0.4L |

| 12.Amount of abrasive in circulation 70¡«80kg |

| 13.Blast wheel |

| £¨1£©speed of impeller 2300rpm/min |

| £¨2£©diameter of blades 380mm |

| £¨3£©inside width of blades 62mm |

| £¨4£©abrasive flow rate 100kg/min |

| £¨5£©velocity of shot 60¡«70m/s |

| £¨6£©rotating direction of impeller (see in the direction of leading pipe): clockwise |

| £¨7£©divergent angle of shot 60¡ã¡«70¡ã |

| £¨8£©abrasive divergent width 100¡«200mm |

| £¨9£©adjusting range of the control cage 10mm |

| 14. Specification of shot |

| diameter 0.8¡«1.2mm |

| 15. Consumption of shot |

| £¨1£©iron castings 5¡«10kg/t |

| £¨2£©steel castings 10¡«20kg/t |

| £¨3£©forgings 8¡«15kg/t |

| 16. Dust collector |

| £¨1£©ventilation capacity 2000m3/h |

| £¨2£©separating efficiency (common green sand) 99% |

| 17. Overall dimension |

| length¡Áwidth¡Áheight 3400mm¡Á2458mm¡Á3370mm |

| 18. Weight of the machine about 3000 kg |

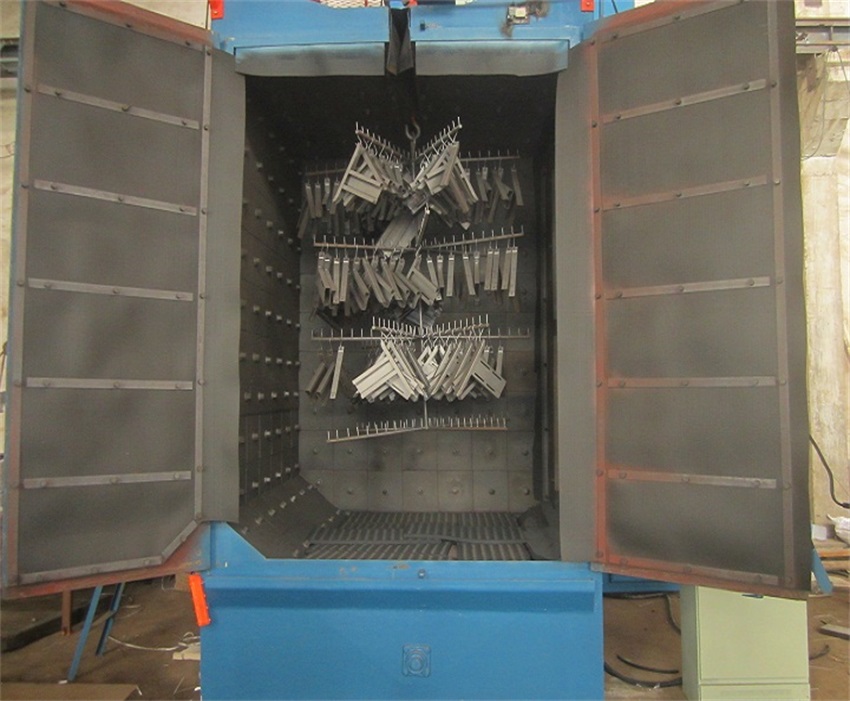

Equipment Features:

This machine consists of blasting cabinet, flapdoor, blast wheel, material feeding device, elevator, separator, dust collector and electric control system.

Its working principle is: In cleaning up the room with a prescribed number of workpiece, after startup of the machine, the workpiece is drives the roller, began to flip, and shot blasting machine, high-speed thrown projectile formed pill beam, uniform blow in the workpiece surface, so as to achieve the purpose of cleaning, strengthening. Projectiles thrown and sand through the hole in the rubber crawler, into ascension machine, by the elevator to the separator to separate. Dust by fan ceiling sent for dust filter, clean air is discharged into the atmosphere, the bag dust by mechanical vibration play fall into the bottom of dust collector dust box, the user can be cleared on a regular basis, sand, waste by waste pipe out, users can reuse. Pill sand mixture by using tube retracted into the body chamber, separator are to be separated and reused, clean the projectile by electromagnetic for pill gate shot into the projectile hit the job.