Contact Now

Contact Now

Q3210 Crawler type shot blasting machine Crawler type shot blasting machine

Machine Description

Supply Professional Customization Design Service. Can design most suitable machine according to your details requirement and workpiece!

The technological strength:

1.The first dedicated shot blasting machine for office building outside wall decoration marble in China;

2.The first dedicated shot blasting machine for aggrandizement floor grinding tool in China;

3.The first dedicated shot blasting machine for high-speed rail, filled the domestic blank in China;

4.The first dedicated shot blasting machine for crystalline silicon;

5.The first dedicated shot blasting machine for oil field special-purpose cable tray;

Shot Blasting Machine Introduct:

Shot blasting machine is a cleaning effect , compact structure, low noise, complete and good cleaning equipment, has the following characteristics:

1. The machine uses cantilever centrifugal blast wheel, has a long life, simple structure and other characteristics.

2. By full curtain winnowing abrasive mixture separator, with good separation effects and higher productivity, has a positive effect to improve the life of the blasting blade.

3. Use wear-resistant rubber track, decreasing workpiece collision damage phenomenon and then reduce the noise of the machine.

4. Use pulse dust collector, dust can be collected in the dust hopper or exclude to outdoors, improve the labor environment.

Tumblast shot blasting machine specification:

Item

Unit

Q326

Q3210

Productivity

kg/h

600-1200

2500-3500

Feeding amount

Kg

200

800

Maximum weight of single piece

Kg

15

30

End plate diameter

mm

650

1000

Effective volume

m3

0.33

1.05

Abrasive flow rate

Kg/min

200

250

Dust removal air volume

m3/h

2500

4000

Power consumption

kw

13.6

25.6

Outside dimension

mm

3200*1650*3800

4290*1950*4500

Features:

Compact design, simple operating principle

Forced but gentle turning and tumbling of the parts for all-round shot impingement

Targeted high performance shot blasting for specific applications

Continuous and thorough shot removal

Applications:

Descaling of forged or heat treated parts

Desanding of ferrous and non-ferrous metal castings

Deburring of metallic and non-metallic parts

Deflashing of die cast parts

Contaminant removal

The tumbling action of the belt conveyor ensures that components are continually exposed to the blast stream and completely cleaned. For easy unloading, the belt conveyor is reversed, delivering the components into the loading skip or stillage.

Optimized shot blast effect:

During shot blasting, the workpieces, regardless of size and shape, are evenly and continuously tumbled. This is necessary for the effective and uniform treatment of all surfaces.

During tumbling, the workpieces continually undergo shot removal, enabling workpiece interiors and cavities to be perfectly cleaned

For the complete removal of all shot, the final tumbling time that follows the shot blast sequence can be regulated to suit the type of workpieces being blast cleaned

The tightly sealed, leak-proof blast chamber minimizes shot consumption.

Advantage£º

This machine is a new product developed by domestic and foreign technology. It is a kind of cleaning equipment with good cleaning effect, compact structure, low noise and good complete set. It has the following characteristics:

1. the machine uses a cantilever centrifugal blast wheel, with long service life, simple structure, etc.

2. using BE type separator, with good separation effect and high productivity, Leaf life has a positive effect.

3. The machine uses bag dust collector, and the dust emission concentration is lower than the national standard, which improves the working environment of workers.

4. Wear-resistant rubber belt is used to reduce collision and damage to the workpiece and reduce machine noise.

5. After the workpiece is cleaned, it can be automatically discharged, which reduces the labor intensity of workers.

Equipment Features:

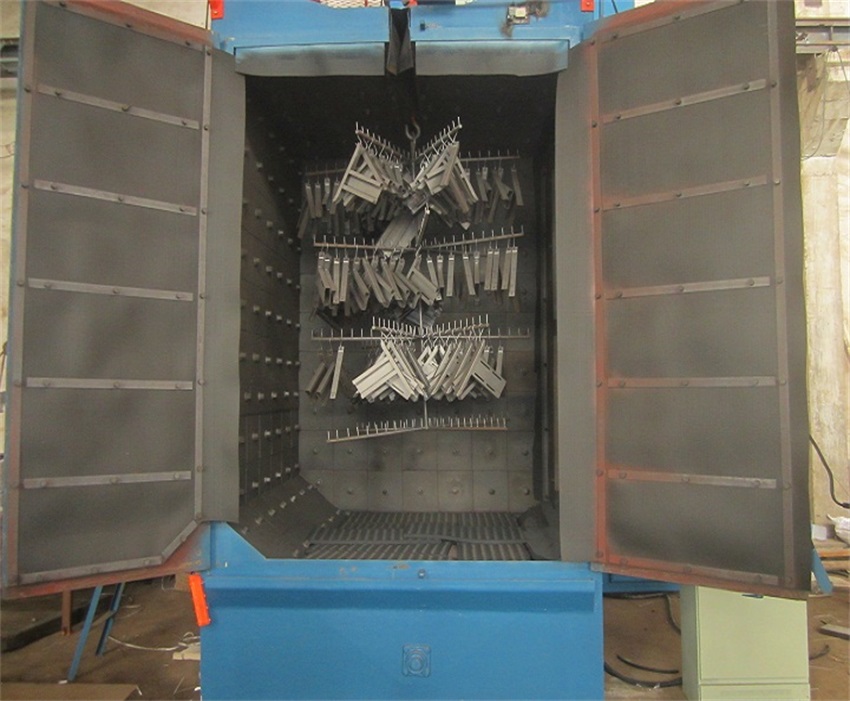

This machine consists of blasting cabinet, flapdoor, blast wheel, material feeding device, elevator, separator, dust collector and electric control system.

Its working principle is: In cleaning up the room with a prescribed number of workpiece, after startup of the machine, the workpiece is drives the roller, began to flip, and shot blasting machine, high-speed thrown projectile formed pill beam, uniform blow in the workpiece surface, so as to achieve the purpose of cleaning, strengthening. Projectiles thrown and sand through the hole in the rubber crawler, into ascension machine, by the elevator to the separator to separate. Dust by fan ceiling sent for dust filter, clean air is discharged into the atmosphere, the bag dust by mechanical vibration play fall into the bottom of dust collector dust box, the user can be cleared on a regular basis, sand, waste by waste pipe out, users can reuse. Pill sand mixture by using tube retracted into the body chamber, separator are to be separated and reused, clean the projectile by electromagnetic for pill gate shot into the projectile hit the job.